Contact us

Xicheng Village, Anguo City, Baoding City, Hebei Province, China

CORRUGATED SIDEWALL CONVEYOR BELT

- Product description

-

Features and application scope

The conveyer belt block selected the most advanced material, adopted the unique technique. The block, the clapboard, and the belt have been combined by the secondary sulfur method. It has the feature of soft in the strong, no degumming, no desquamate, with the new structures of laniate resistant, and twist resistant. At the same time, it has the common features as the general conveyer belt, such as the large angle of transfer, the agility of the angle change, the low cost of the energy, and the high efficiency of work etc.. It is in line with HG/T4062-2008.

Usage

The conveyer belt block is widely used in transferring in ports, metallurgy, mine, electric, coal, foundry, building materials, food supplies, and fertilizer etc. It can make the supplies in bulk transfer continuously in the angle of 0-90. It has the advantage of large angle of transferring, large range of usage, small occupy of covering, no transfer point, low investment in construction, low expense in maintenance, large quantity in transfer etc. It has solved the problem of the unreachable transfer angle of general conveyer belt and pattem conveyer belt. The conveyer belt block can design an entire set of transfer system according to the environment to avoid the coe-fficient of enhancement for gap transfer and complex transfer.

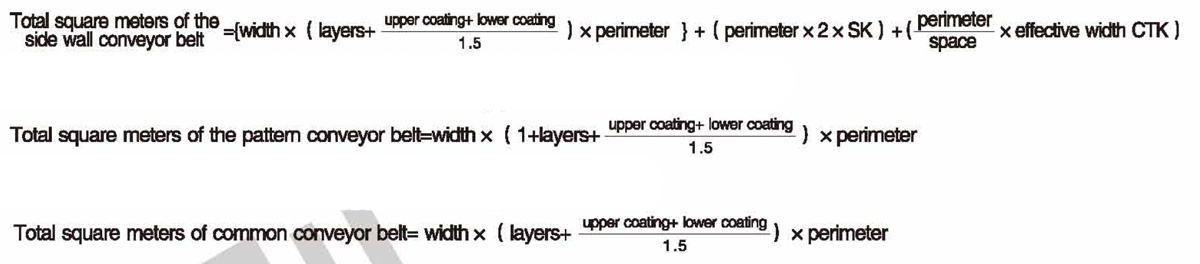

The conveyer belt block can transfer various suppliers in the angle of level, slope, apeak and other changeable angle; no matter it is coal, mine, sand, fertilizer or food stuff. The size of the granularity less than 400mm has no restrictions, and the quantity of transfer can be chosen from 1cub meter /h to 6000 cub meter/h.Calculation method

Specifications of kinds of side wall conveyor belt

Type of side wall Block height

(H)Block width

(BW)Wave distance

(T)Bottom plate width

(BF)Square meter /m

(SK)Adapted clapboard

(H)Clapboard type Bottom plate width

(BF)Square meter /m

(SK)S 60 44 42 45 0.61 50 CT 55 0.55 S 80 44 42 50 0.75 75 CT 70 1.29 S 120 44 42 50 1.69 110 CT 100 1.76 S 160 65 65 80 2.68 150 CT 100 2.24 S 200 70 65 90 3.53 180 CT 160 3.39 S 240 80 65 90 4.75 220 CT 160 5.00 S 300 90 70 95 7.03 280 CT 180 7.05

Company Profile

Hebei Dongsheng Rubber Co., Ltd. was founded in 1980 and was originally known as Dongcheng Belt Factory of Anguo City. After years of practical research and unremitting efforts, it has now developed into a modern enterprise of a certain scale.

The company covers an area of 11,000 square meters and has a construction area of 4,500 square meters. It is engaged in the production, service and business activities of rubber products and conveying machinery. We can produce various specifications of ordinary conveyor belts, high-strength conveyor belts, heat-resistant, flame-resistant, acid and alkali resistant, hermetic patterned conveyor belts, pitted conveyor belts, parallel transmission belts and various idlers, brackets, transmission rollers and other conveyor machinery parts.

Customization

Customer Inquiry

Factory Quotation

Customer Orders

Factory Production

Quality Testing

Packaging & Shipping

FAQ

Can you accept small quantities?

Yes, small batches are accepted, and delivery is fast

Do you have pre-shipment inspection procedures?

Yes, we always test the product before delivery.

Can I take a sample for testing?

Yes, samples can be sent for testing before bulk orders.

What is the delivery time?

Inventory orders take 7-15 days, while OEM and ODM orders depend on the specific circumstances.

What are the payment terms?

Wire transfer or Letter of Credit, Western Union, Alipay, etc.

Can I have my own customized product?

Yes. OEM and ODM services are available, including design, logo, and packaging.

Keywords: